PROTEGO® Solutions for Alcohol Applications

PROTEGO® offers various solutions for the protection of storage tanks for ethanol and other alcohols.

Please note that the solutions presented here are just examples; we work closely with our customers to provide tailored safety solutions for their specific operational needs and to comply with local regulations and standards.

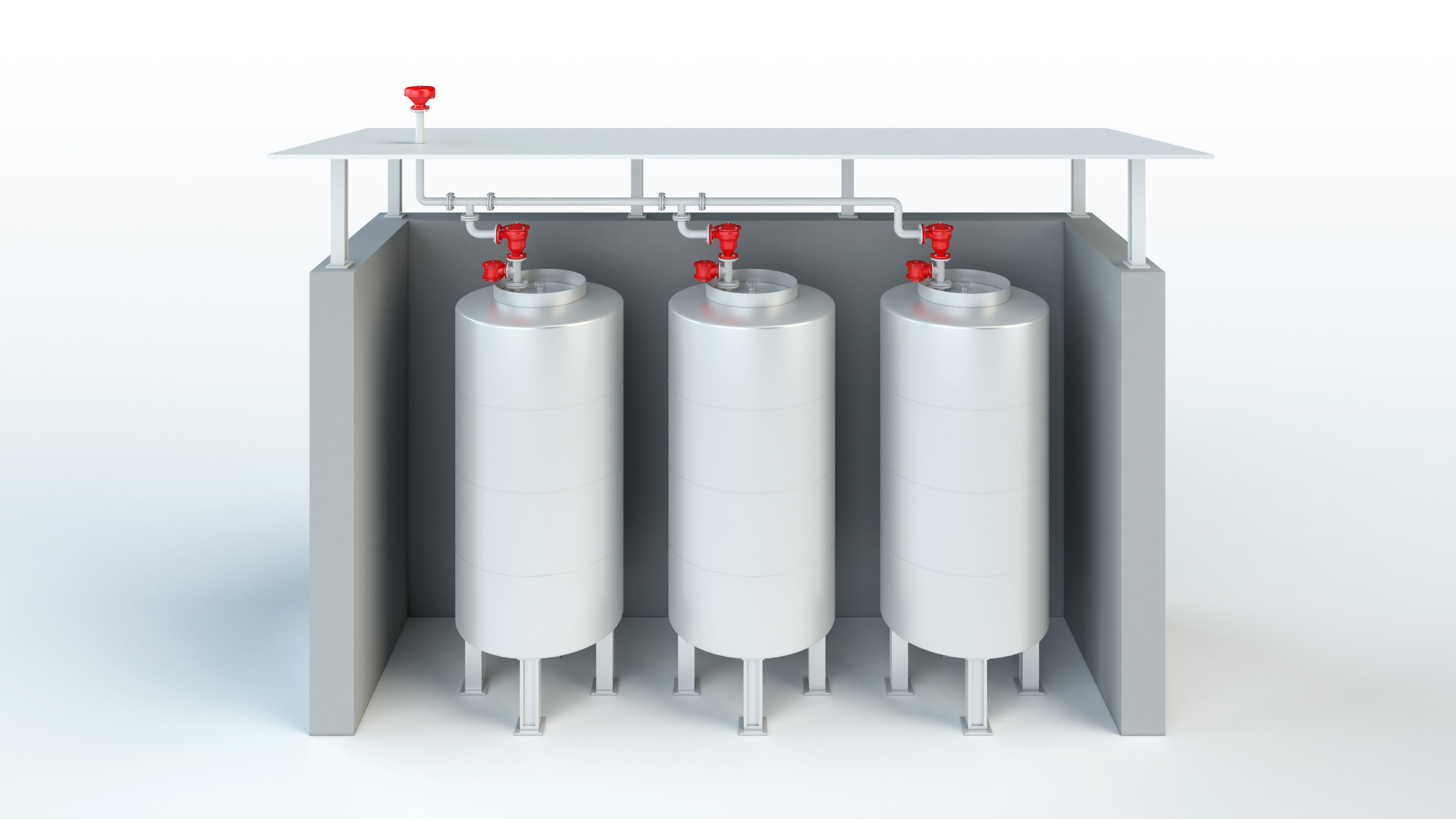

Examples of the protection of free-standing alcohol storage tanks with Emergency Relief Valve

Emergency Relief Valves are required when storage tanks are designed for the so called fire-case and they are not executed with a frangible roof-to-shell connection.

Deflagration Flame Arrester and Emergency Relief Valve

End-of-line Deflagration Flame Arrester PROTEGO® LH/AD

Emergency Relief Valve PROTEGO® ER/VH

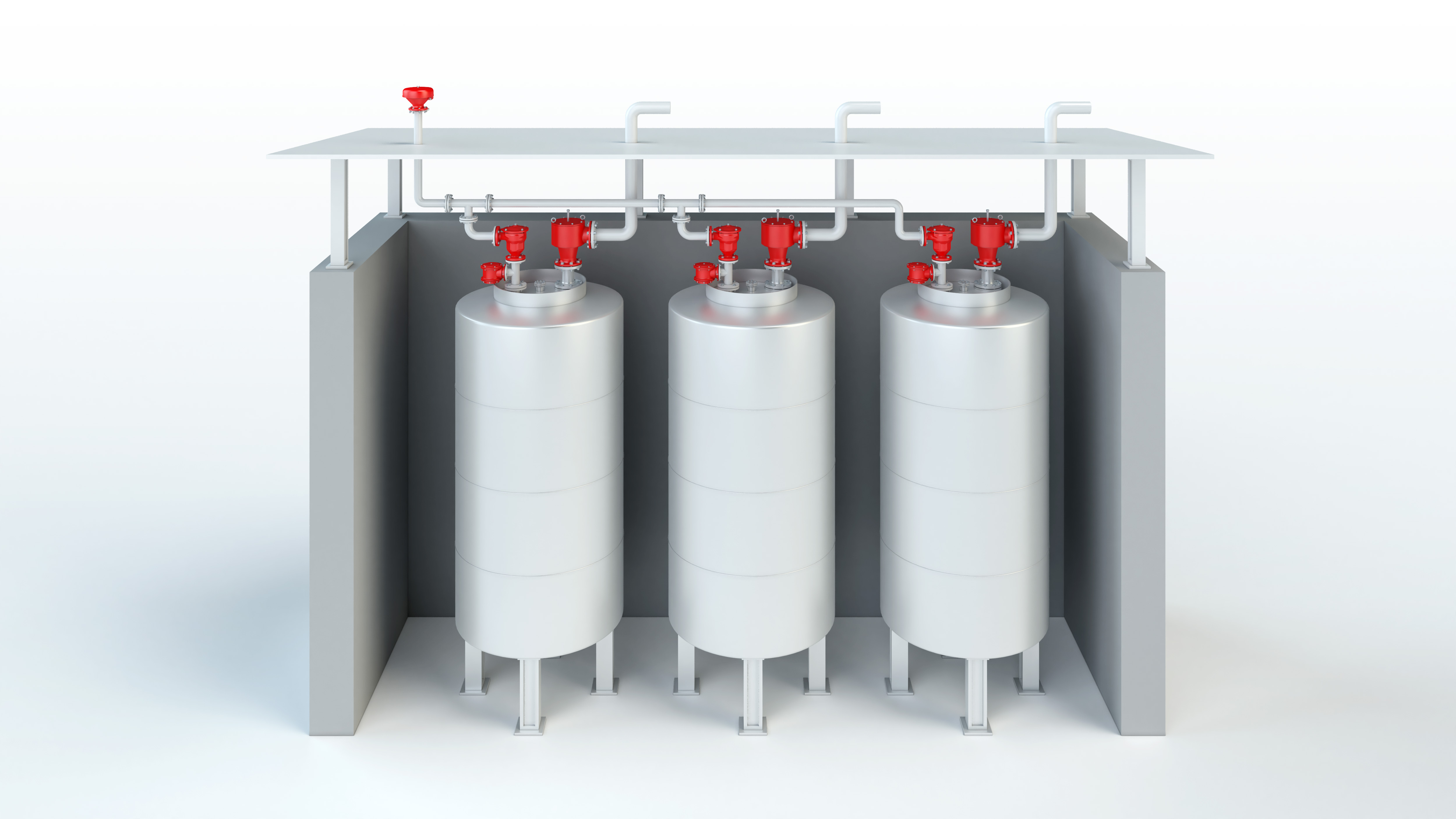

Breather Valve and Emergency Relief Valve

Pressure/Vacuum Relief Valve PROTEGO® VD/TS, atmospheric deflagration-proof

Emergency Relief Valve PROTEGO® ER/VH

The PROTEGO® VD/TS with integrated Flame Arrester provides certified explosion protection and flow capacity as well as ease of maintenance

Pressure Relief Valve, Vacuum Relief Valve and Emergency Relief Valve

Deflagration-proof Vacuum Relief Valve PROTEGO® SV/E

Emergency Relief Valve PROTEGO® ER/VH

Pressure Relief Valve PROTEGO® P/EBR-E, deflagration- and endurance burning-proof for alcohols

Endurance burning-proof required depending on local standards and regulations

Examples of the protection of free-standing alcohol storage tanks without Emergency Relief Valve

Other solutions for fire case venting could be a bursting discs or frangible roof-to-shell connection which would replace the requirements for an Emergency Relief Valve.

Deflagration Flame Arrester

Endurance burning proof end-of-line Deflagration Flame Arrester PROTEGO® BE/HR-E for alcohols

Endurance burning-proof required depending on local standards and regulations

Breather Valve

Pressure/Vacuum Relief Valve PROTEGO® VD/TS, atmospheric deflagration-proof

The PROTEGO® VD/TS with integrated Flame Arrester provides certified explosion protection and flow capacity as well as ease of maintenance

Pressure Relief Valve and Vacuum Relief Valve

Pressure Relief Valve PROTEGO® P/EBR-E, deflagration- and endurance burning-proof for alcohols

Deflagration-proof Vacuum Relief Valve PROTEGO® SV/E

Endurance burning proof required depending on local standards and regulations

Examples of the protection of roofed alcohol storage tanks

When protecting storage or process tanks under roof the venting above the roof is highly recomended. Often in-line Flame Arresters are used. The max. possible run-up distance from source of ignition till point of installation of the Flame Arrester (L/D-ratio) is to be observed.

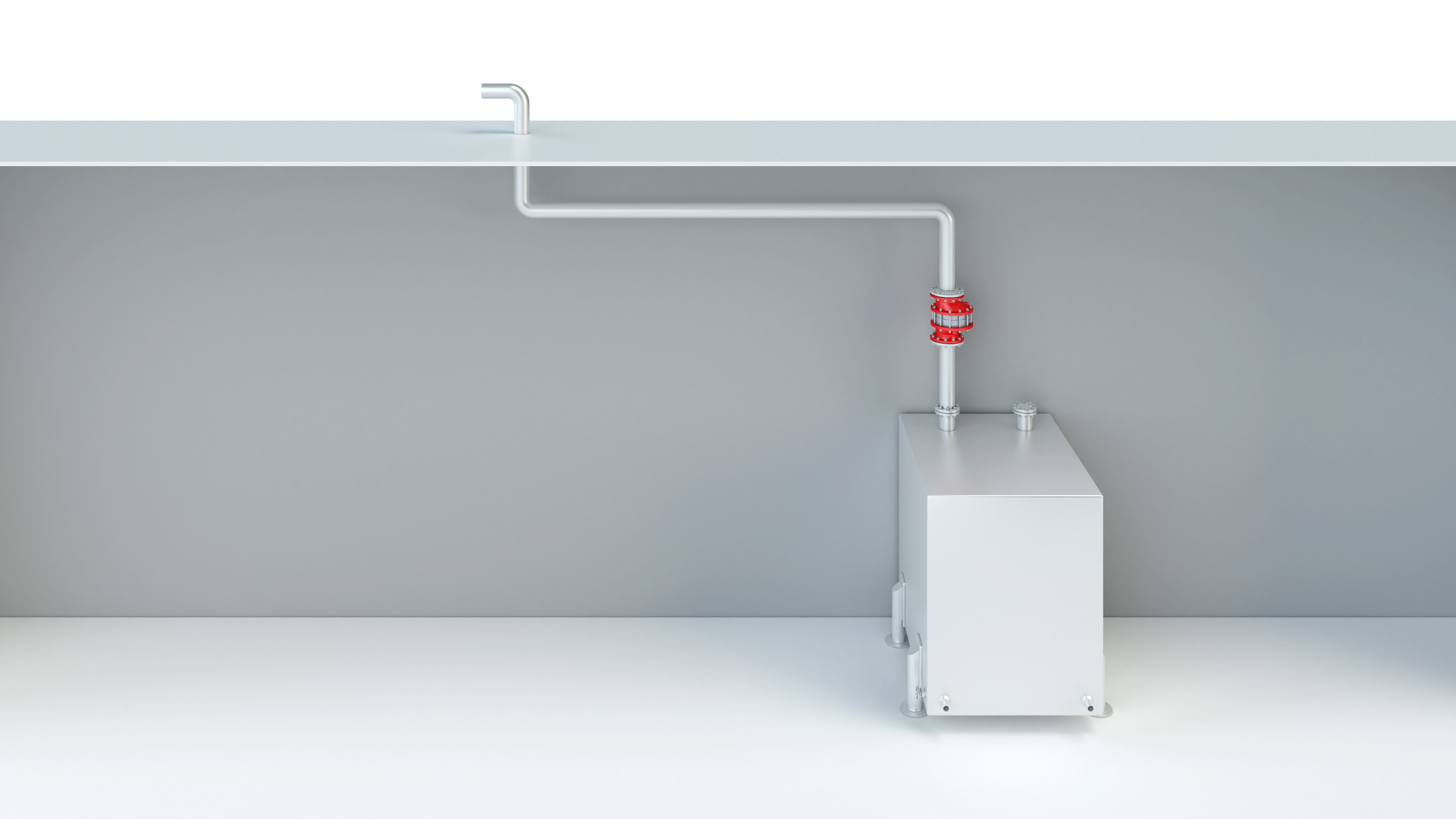

Protection of Stills

Deflagration-proof, end-of-line Deflagration Flame Arrester PROTEGO® LH/AD

Pressure Relief Valve PROTEGO® DZ/E-F and deflagration-proof Vacuum Relief Valve PROTEGO® SV/E

Rapid opening of the Vacuum Valve with PROTEGO® 10% technology provides maximum protection for the still against vacuum collapse.

In-line Detonation Flame Arrester

Protection of roofed spirit receiver vessels with eccentric Detonation Flame Arrester PROTEGO® DA-E-IIB3.

The location of PROTEGO® DA-E is not restricted.

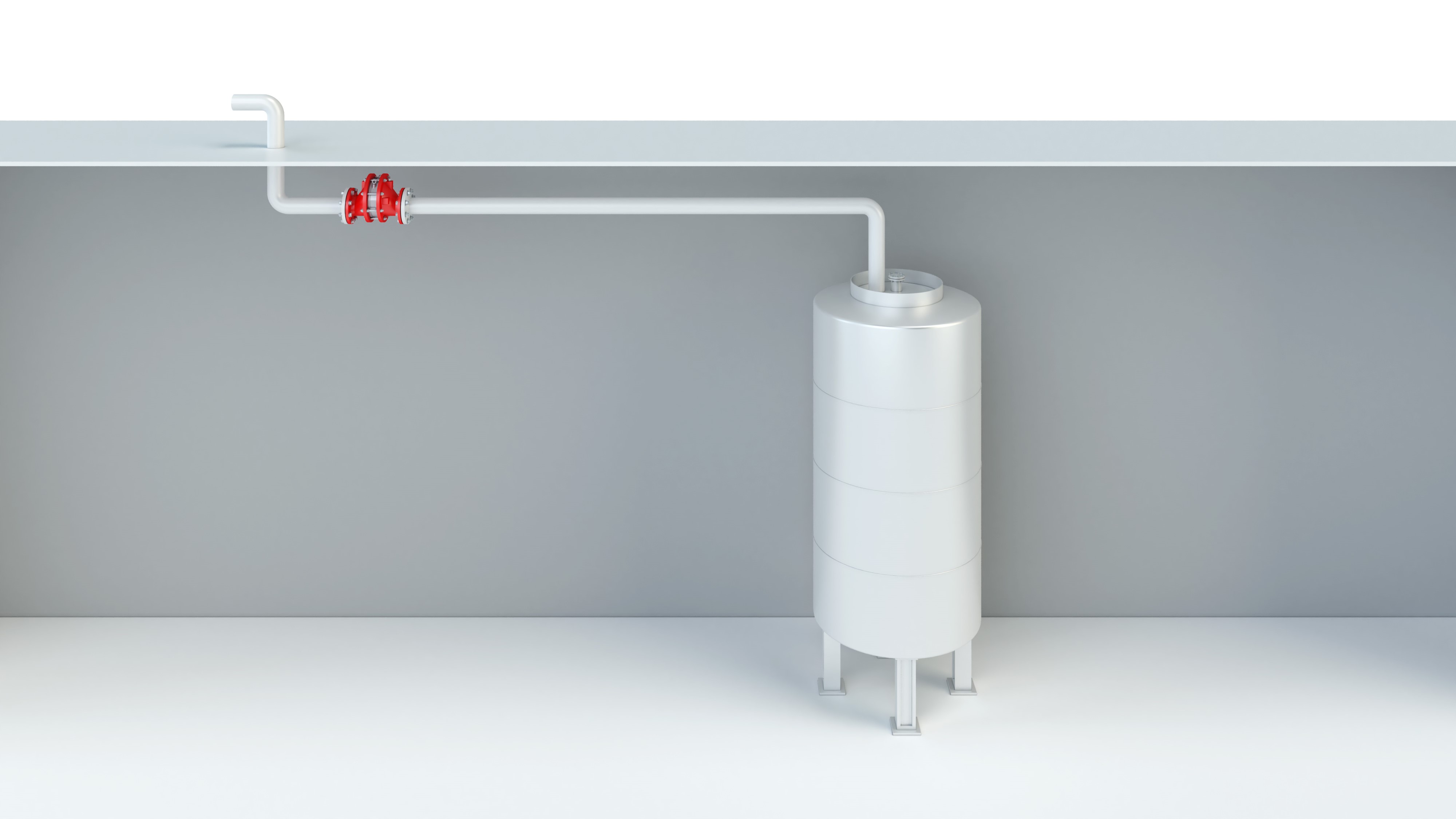

In-line Deflagration Flame Arrester

Protection of roofed spirit receiver vessels with eccentric Deflagration Flame Arrester PROTEGO® FA-E-IIB3 (L/D ratio <=50).

In-line Detonation Arrester, end-of-line Flame Arrester and Vacuum Relief Valve

Deflagration-proof Vacuum Relief Valve PROTEGO® SV/E

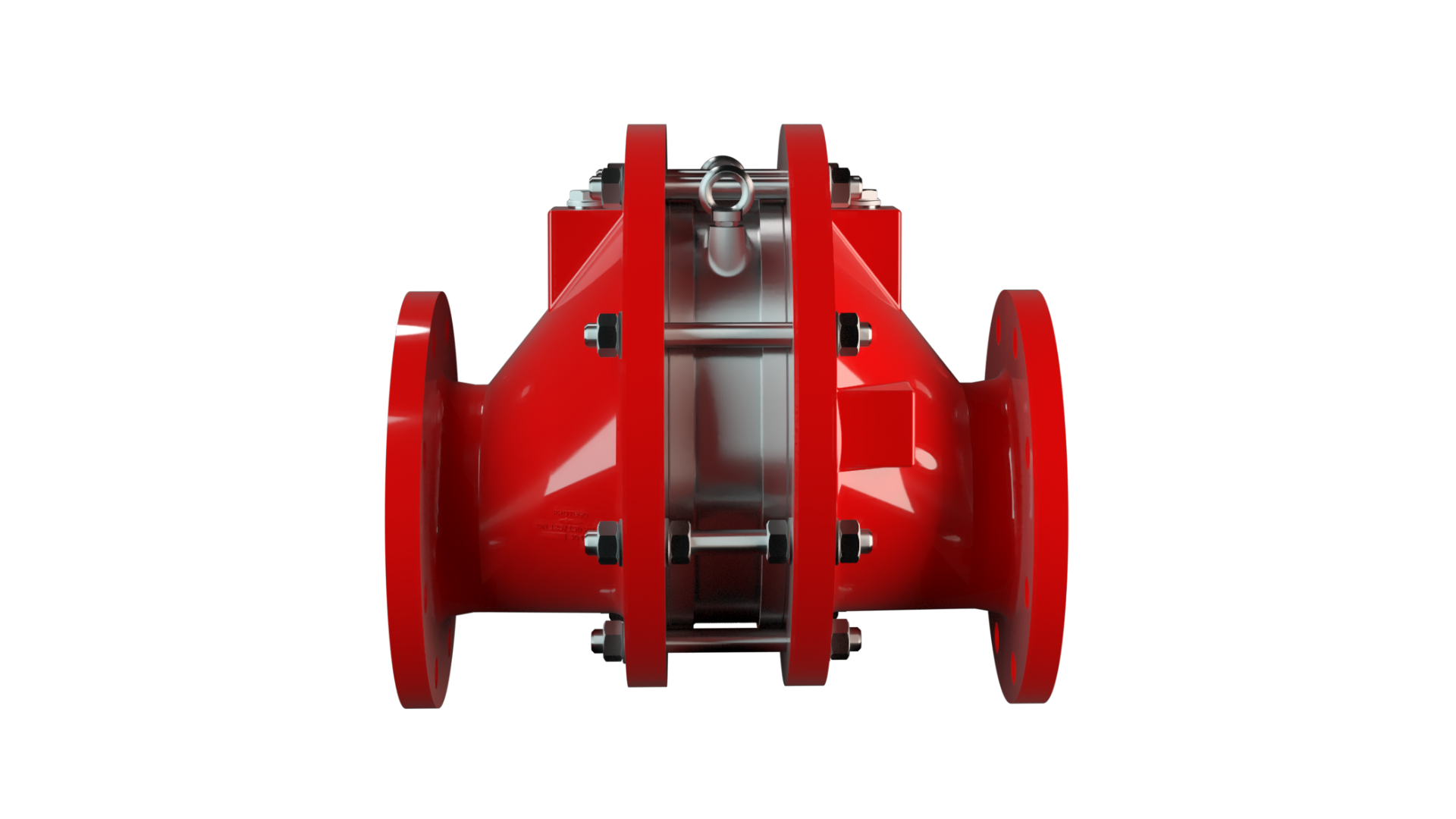

Detonation Flame Arrester PROTEGO® DR/ES or PROTEGO® DR/ES-V with integrated Check Valve

The venting line is designed to provide venting to a safe location and is protected with a deflagration proof end-of-line Flame Arrester PROTEGO® LH/AD or an endurance burning proof end-of-line Deflagration Flame Arrester PROTEGO® BE/HR-E for alcohols. Endurance burning-proof required depending on local standards and regulations.

In-line Detonation Arrester, end-of-line Flame Arrester, Vacuum Relief Valve and Emergency Relief Valve

Deflagration-proof Vacuum Relief Valve PROTEGO® SV/E

Detonation Flame Arrester PROTEGO® DR/ES or PROTEGO® DR/ES-V with integrated Check Valve

The venting line is designed to provide venting to a safe location and is protected with a deflagration proof end-of-line Flame Arrester PROTEGO® LH/AD.

In-line Pressure Relief Valve PROTEGO® D/PAL for emergency relief venting.

Research and Development for Alcohol Applications

Key components to obtain products of high quality and technical perfection, are ongoing development and research, but also testing our devices under extreme conditions.

PROTEGO® operates the world’s largest research and development center for product innovation, general research projects, and custom applications.

Our team of engineers and specialists will help you select, develop and optimize equipment parts and devices to ensure the safe storage of alcohol in regards to

- overpressure and vacuum

- deflagrations

- detonations

- fire

Advantages of PROTEGO® Valves and Flame Arresters

PROTEGO® Valves

The extreme tightness of PROTEGO® ZETOP Valves guarantees Zero Emission at Tank Operating Pressure.

PROTEGO® 10% full-lift technology vents are a major benefit to emission reduction and to safe process plant operation.

PROTEGO® Deflagration/Detonation Flame Arresters

Maintenance-friendly design i. e. modular design enables replacement of the individual FLAMEFILTER® discs.

Minimal pressure loss resulting in low operating and lifecycle costs.

EU conformity according to the currently valid ATEX directive.

What about your application?

Contact our specialists for your individual requirements.